Manufacturing low carbon intensity renewable oil from low value plastic waste.

Ultrafima plays a role in the circular economy by transforming plastic waste into a renewable oil that can be a substitute for virgin crude oil.Our low carbon intensity oil can be processed with crude oil in refineries and gives refineries the opportunity to generate carbon credits.

Currently under development in Canada, the ULTRAFIMA plant will produce 50 million litres of a low carbon intensity renewable oil from plastic.

The Science and Process

Our planned facility will transform existing plastic and rubber waste products into low carbon intensity renewable oil through a pyrolysis process.

With over 20 years experience in plastic recycling, our facility will collect, sort and prepare the right plastic and rubber waste products for processing.

This process will reduce greenhouse gas (GHG) emissions by 10,000 tonnes CO2e annually.

The Ultrafima facility will divert 70,000+ tonnes of materials from landfills annually.

This low carbon intensity renewable plastic oil will be suitable for refineries to co-process with crude oil into finished products.

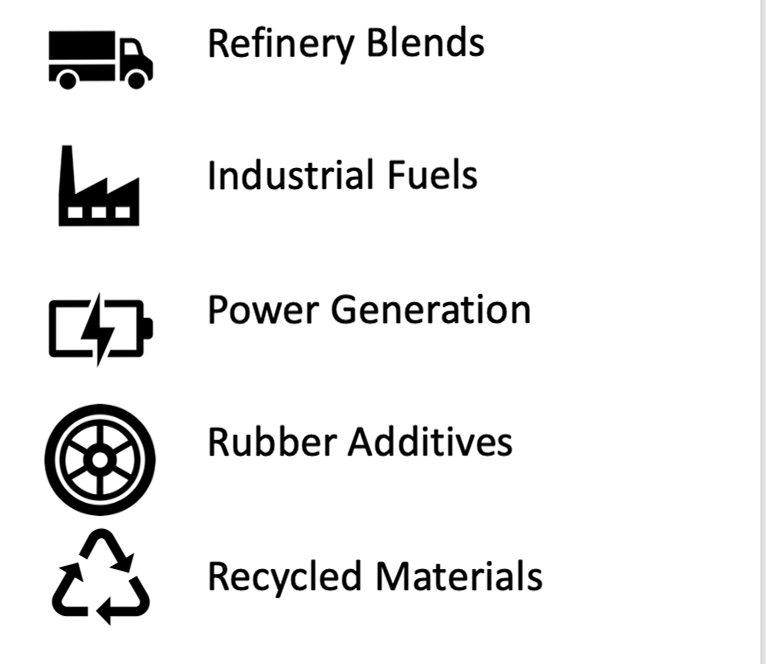

Products

The planned facility has the capacity to receive and process 230 tonnes of plastic and rubber feedstock per day. Output is projected to reach:

50 million liters/year of Low Carbon Intensity Crude Oil

10,000 tonnes/year of Synthetic Gas

10,000 tonnes/year of Carbon Black Charcoal

With an additional by-product of 420 tonnes/year in steel from tires.

Applications

Standards, Regulations, and Commitments

“Overall, Canada’s per capita GHG emissions are very high, earning Canada a “D”—only the U.S. and Australia fare worse.”

– Canadian Conference Board

ULTRAFIMA is a leader in the manufacturing and delivery of low carbon alternative energy.

Action on climate change is underway. We aim to accelerate the process for companies required to reduce their carbon footprint. Canadian companies are subject to:

- The Clean Fuel Standard (CFR) is designed to “significantly reduce pollution by making the fuels we use daily, cleaner.” In conjunction with the Clean Fuel Regulations, it sets out to support the companies making the transition. This system includes a credit market for producers and importers of gasoline and diesel where companies create or purchase credits to be which are applied to their compliance reduction requirements.

- 2030 Emissions Reduction Plan: Clean Air, Strong Economy: Driving down carbon pollution in the oil and gas sector